Trough ironing machine

Product Details

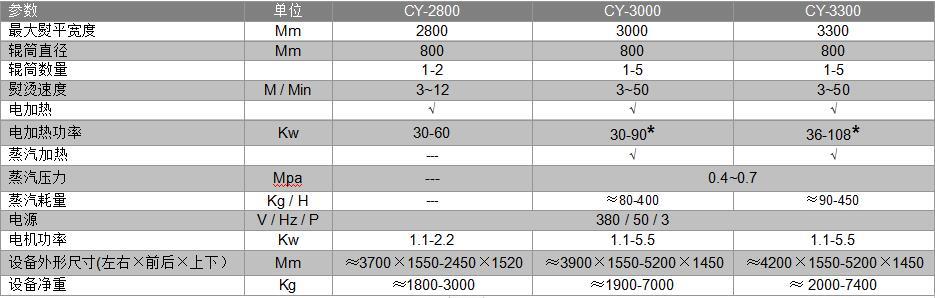

* Note: Our company recommends that more electric heating ironing machines do not exceed 3 rollers

Foshan Industrial Washing Machine has poured more than 20 years of manufacturing experience and carefully improved a new generation of products for us. In terms of transmission, heat insulation, dehumidification, etc., the efficiency has been greatly improved compared with the previous generation of slot-type ironing machines.

C series trough ironing machine has three ironing widths (2800, 3000 and 3300mm), two heating methods (electric heating or steam heating) and multiple configuration options (single roller to higher five rollers). Forward and backward.

Design of ironing trough * The design and manufacturing process of ironing trough are only designed to bring better ironing results to the user. The excellent selection of materials, the construction in accordance with geometric principles and the polished surface are all aimed at improving the quality of ironing.

* The trough body is self-supporting structure, which is strong and not deformed. Together with the lifting rollers, it forms a high-efficiency ironing system. The roller can be automatically raised after stopping to prevent the felt from sticking to the tank.

* The bottom of the ironing tank is treated with heat insulation to prevent the heat from radiating and cause the temperature in the work room to rise, while maintaining the temperature of the ironing tank to reduce energy consumption.

Roller design * The flexible layer formed by the iron felt wrapped roller made of stainless steel spring and imported materials, presses the linen on the ironing trough with a consistent pressure during the ironing process to ensure the ironing effect.

Dehumidification system * The perforated small holes on the rollers are matched with stainless steel springs and ironing felts. In conjunction with the roller dehumidification system, the moisture evaporated during ironing is taken away in time to ensure that the felts and ironing tanks are dry and the ironing effect is guaranteed.

* Innovative top micro airflow dehumidification system, which directly takes away the hot and humid steam rising during ironing through the micro airflow, keeping the work room cool and dry.

Control * The product uses a variable frequency drive mechanism, and the operator can adjust the ironing speed in real time according to the type of linen and humidity to improve work efficiency.

Safety * Anti-rolling safety baffle is equipped at the feed end to prevent accidents.

Previous: washing machine